CE/ ISO Certified Cryogenic cylinders liquid oxygen nitrogen argon CO2 LNG tanks dewar flasks

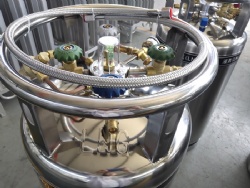

Vacuum Welding Insulated Cryogenic Portable Liquid Oxygen nitrogen argon CO2 LNG Cylinders (PLC)

A portable cryogenic liquid cylinder is a container designed to store and transport cryogenic liquids, such as liquid nitrogen, oxygen, or argon, at extremely low temperatures. These cryogenic cylinders are typically made of stainless steel and have a vacuum chamber between the inner and outer walls to minimize heat transfer and maintain the temperature of the contents. They may be equipped with valves, pressure relief devices, and other safety features to ensure safe handling and storage of cryogenic liquids. Portable cryogenic liquid cylinders are commonly used in medical, research, and industrial applications where a reliable and convenient source of cryogenic liquids is required.

Minwen's portable cryogenic dewar storage cylinders specification.

Minwen's portable cryogenic dewar storage cylinders specification.

1. Capacity: 80L, 100L, 175L, 195L, 210L, 360L, 500L

2. Medium: Liquid oxygen, nitrogen, argon, carbon dioxide and LNG.

3. Working pressure: 1.37MPa, 2.3MPa, 2.88MPa, 3.45MPa, etc.

4. Evaporation rate (% per day): ≤ 2.1 (LIN)

5. Surface treatment: Polish

6. Liquid level gauge: Floate

7. Mateiral: 304 Stainless steel for inner and outer vessel

8. Application: This is applied to store, transport the liquefied gas for scientific research, laser cutting, chemical, electronic industries, fishing, medeical and public utiliteis.

Advantages of Minwen's cryogenic liquid cylinders dewar flasks.

1. The cryogenic liquid cylinders are easy to use, safe and reliable, economical and durable.

Advantages of Minwen's cryogenic liquid cylinders dewar flasks.

1. The cryogenic liquid cylinders are easy to use, safe and reliable, economical and durable.

2. The support system of the inner vessel is made of stainless steel to achieve the purpose of low heat loss and high strength.

3. It is easy to use and can be operated independently by a single person.

4. Clients can store pure cryogenic liquid with large storage capacity.

5. The internal pressure of the cryogenic cylinders will rise during the deactivation phase after flling. The cryogenic cylinders have a high-performance insulation system, so the pressure rise rate is low. Under normal circumstances, there is no need to reduce the pressure through a safety valve.

6. The built-in supercharger and vaporizer of the cryogenic cylinders can realize continuous supply of either gas or liquid. There is no need to install an external vaporizer under the designed capacity.

|

Technical Parameter of 175 liter PLC Portable liquid cylinders |

||

|

Model |

DPL450-175-1.4/2.3/2.88 |

|

|

Max liquid capacity(L) |

175 |

|

|

Medium |

liquid oxygen,liquid argon,liquid nitrogen,liquid carbon dioxide, LNG. |

|

|

Usable liquid capacity(L) |

166 |

|

|

Size(mm) |

φ511*1541 |

|

|

Empty weight(Kg) |

115/132/148 |

|

|

Servise pressure(Barg) |

14/23/28.8 |

|

|

First pressure relief valve setting(Barg) |

16.8/27/34.5 |

|

|

Bursting disc setting/Second pressure relief(Barg) |

24.1/41/51 |

|

|

Normal evaporation rate (LN2)(%/d) |

≤2.1 |

|

|

Gas withdraw rate/N2(NM3/h) |

9.2 |

|

|

Min working temperature(℃) |

-196 |

|

|

Hydraulic test pressure(Barg) |

28/46/57.6 |

|

|

Leakage test pressure(Barg) |

14/23/28.8 |

|

|

Max filling (Kg) |

LO2 |

189 |

|

LN2 |

134 |

|

|

LAr |

234 |

|

|

LCO2 |

183 |

|

|

LNG |

71 |

|