Hydrogen Generator ALK Water Electrolysis H2 Plant

Hydrogen Generator ALK Water Electrolysis H2 Plant with KOH

Within the portfolio of energy storage technologies, hydrogen is widely recognized as a promising option for storing large quantities of renewable electricity over longer periods.

The most established technology option for producing hydrogen from electrical power sources is water electrolysis (WE). With a 100% renewable energy power mix, water electrolysis can produce GREEN HYDROGEN with zero CO2 emissions.

Working principle:

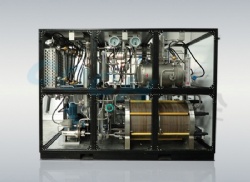

The equipment uses hydroelectricity to generate hydrogen and oxygen for separation, and controls the hydrogen and oxygen level to ensure the purity of hydrogen, and then the hydrogen washing, gas-liquid separation, cooling treatment after the output of product hydrogen.

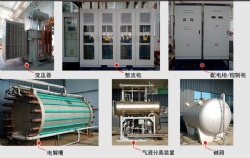

Structure feature:

1. Electrolytic tank: applying brand-new structure design, low inner-electrode voltage, high current density, and low energy consumption per unit of hydrogen production.

2. Gas/liquid separator: simplifying the previous product structure, which makes the space smaller and better effects of gas/liquid separation.

3. Explosion-proof requirements: all the parts are designed as explosion-proof. Clients can choose the appointed brand parts if they require.

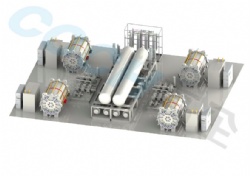

4. Cabinet: one integrated cabinet or split-type, even containerized type for client’s convenient use.

5. Pipes: all pipes are made of SS304 stainless steel and connected in the form of live joints, which changes the disadvantages of traditional flanges that are cumbersome and bulky, decreasing the user's maintenance cost and making the equipment space more reasonable, reducing the floor space.

Working conditions:

1. This equipment cannot be used in the open air, and it should has protection measures against rain, lightning and rodents.

2. Good ventilation must be ensured in the place where the equipment is installed and used, and there should be a ventilation device at the top of the place where the equipment is placed to ensure that gas will not accumulate.

3. The on-site ambient temperature is guaranteed to be above 0°C and below 40°C.