20Nm3/h Onsite 99.5% Purity PSA Medical Oxygen Plant for Hospitals

On-site PSA Oxygen Production Plant 93% Purity Automatic O2 Generators

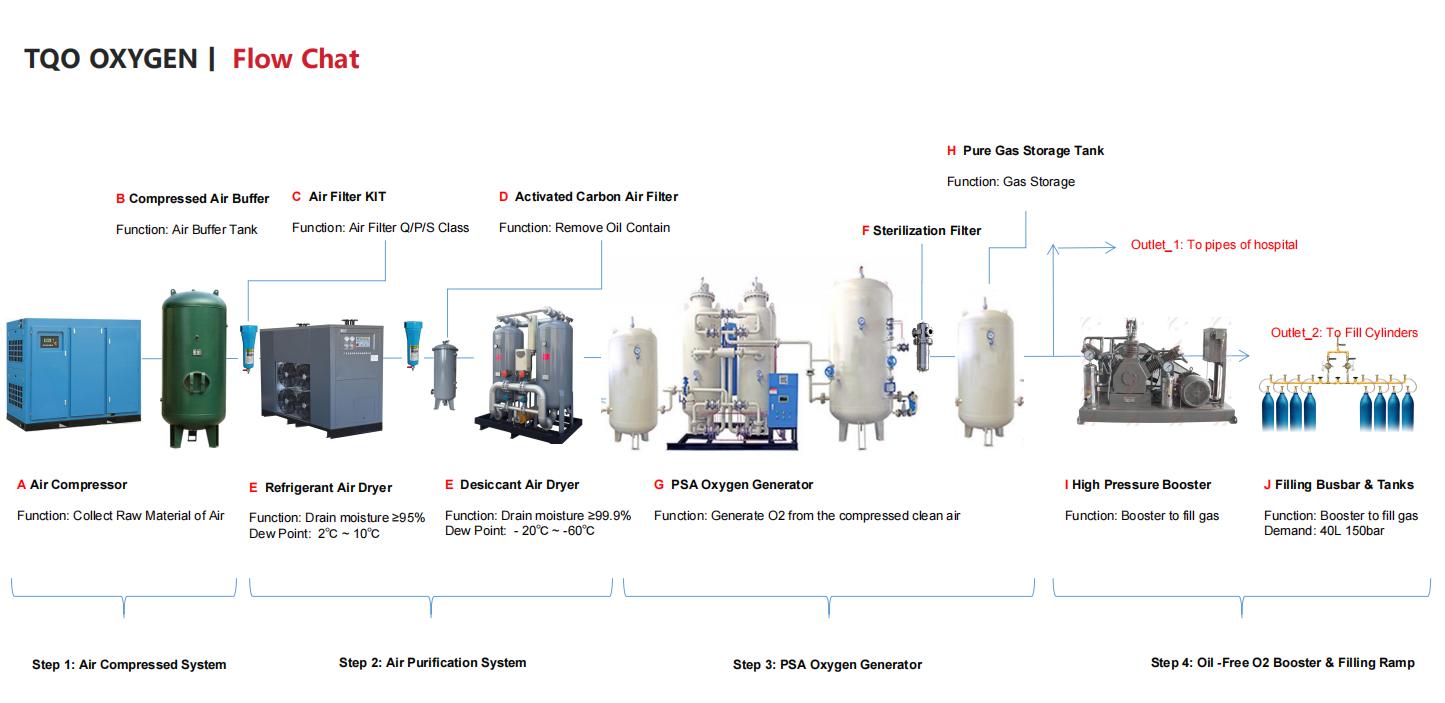

Working Status Process of Minwen PSA oxygen plants.

Step_1: Air Compressed System

The oxygen content in the air is about 21%. This system uses an air compressor to collect air raw materials. Then the compressed air will be stored in the air receiver.

Step_2: Air Purification System

After the compressed air passes through the Refrigerated Air Dryer , the gas enters the Refrigerated dryer to drop down the atmospheric dew point of the compressed air down to 2-10°C, remove a large amount of air moisture, and then primary filtration for the first to remove the oil, water, and dust, then pass through intermediate filtration. The filter removes oil and water so that the oil content is less than or equal to 0.01ppm, and the dust content is less than or equal to 0.01μm; then goes through the activated carbon filter to remove acid, alkali and other harmful gases and micro-oil mist to make the oil content less than or equal to 0.003ppm, and finally go through precision filtration and Dust filtration to get a clean air source.

Step_3: PSA Oxygen Generator

The clean compressed air enters the air buffer tank of the oxygen generator and then enters the two pressure swing adsorption separation towers filled with adsorbent (zeolite molecular sieve, composite bed structure). Compressed air enters from the bottom end of the adsorption tower. After the gas flow is diffused through a special multi-layer stainless steel air diffuser, it evenly enters the adsorption tower for oxygen and nitrogen adsorption and separation. Then oxygen flows out from the outlet end, and a small amount of oxygen enters the regeneration tower to blow the adsorbent to remove the adsorbed impurity components (mainly nitrogen) back to the atmosphere. The two adsorption towers are operated alternately and cyclically, continuously feeding raw material air and continuously producing oxygen.

The oxygen from the oxygen generator enters the oxygen buffer tank and is filtered by the dust filter to obtain the oxygen product. The finished product then stored in a buffer

Step_4: Oil Free O2 Booster

Due to the characteristic of the absorbent of the Zeolite Molecular Sieve, the outlet pressure will be only no more than 0.4Mpa, the high pressure oil-free booster is needed to boost the oxygen gas up to 10bar or 200bar to fill the cylinders based on the customers’ need.

Technical specification of Minwen 50Nm3/h@93%±3% 4bar PSA Oxygen Plant

|

No |

ITEM |

SPECIFICATION |

P/N |

QTY |

|

1 |

PSA OXYGEN GENERATOR |

50Nm3/h 93%±3% 150bar |

TQO50-95 |

1 SET |

|

|

1.1 Screw Air Compressor |

90KW AIR COMPRESSOR |

HD-90 |

1 UNIT |

|

|

1.2 Air Receiver |

2.5m3 0.8Mpa |

CG2.5/0.8 |

1 UNIT |

|

|

1.3 Refrigerated Air Dryer |

17.5Nm3/min 1.0Mpa |

TQ-150AS |

1 UNIT |

|

|

1.4 Air Filter Kit |

17.5Nm3/min 1.0Mpa |

TQ-180KIT |

1 SET |

|

|

1.5 Adsorption Air Dryer |

17.5Nm3/min 1.0Mpa |

TQ-150XF |

1 UNIT |

|

|

1.6 Air Buffer |

2m3 0.8Mpa |

CG2.0/0.8 |

1 UNIT |

|

|

1.7 PSA Oxygen Generator |

50Nm3/h 93%±3% 4bar |

TQO50-93 |

1 UNIT |

|

|

1.8 O2 Buffer 1 |

1.5m3 30.8Mpa |

CG1.5/0.8 |

1 UNIT |

|

|

1.9 O2 Buffer 2 |

0.6m3 0.8Mpa |

CG0.6/0.8 |

1 UNIT |

|

|

1.10 O2 Booster |

50Nm3/h 150bar |

TQOB50-150 |

1 UNIT |

|

|

1.11 Filling Ramp |

10 Gas Taps |

TQBBS2-10 |

1 UNIT |

|

|

1.12 Pipes & Valve Accessories |

Based Actual To the System |

N/A |

1 UNIT |

System overview of Minwen PSA Oxygen Plants is as below.