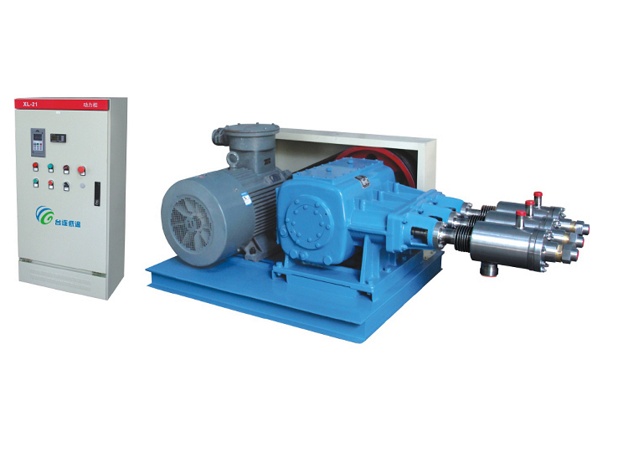

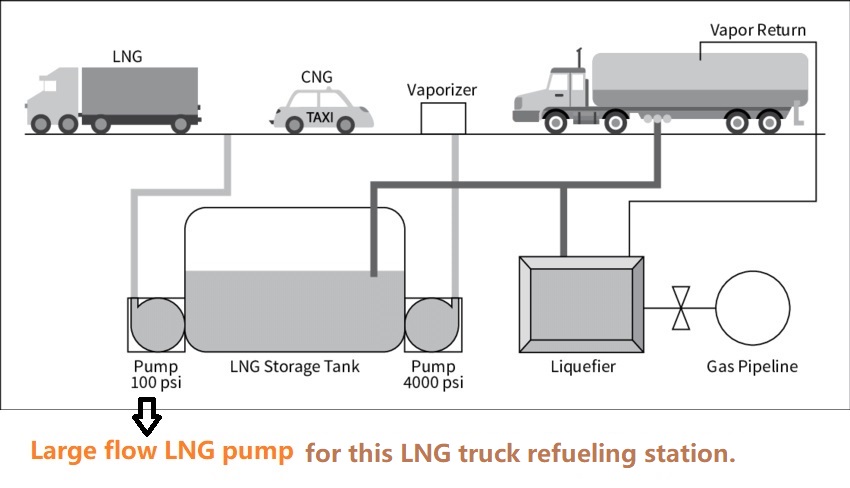

Large Volume Reciprocating LNG Transfer Pumps for LNG Loading/Unloading

Large Volume Low Pressure Reciprocating LNG Transfer Pumps for LNG Loading/Unloading

General introduction of Minwen's piston LNG transfer pumps.

1. This product is suitable for transferring cryogenic liquid medium. In order to ensure safe and reliable use, all parts in contact with low temperature liquid must be degreased.

2. The product outlet piping system must be equipped with a safety valve and a pressure protection device. When the fluid pressure exceeds the set pressure value, the safety valve must work normally and reliably. The pressure protection instrument must correctly and reliably control the motor to stop rotating, and then the pump stops working.

3. Installation and construction of cryogenic liquid pumps and pipelines must comply with relevant national standards.

4. Electrical and instrument installation of low-temperature liquids of flammable and explosive medium must be installed and constructed according to the explosion-proof grade required by the medium and should comply with relevant national standards.

Advantages of Minwen's LNG piston transfer pumps.

1. Single or multiple cold end design to meet various flow rates, reduce the flow impulse;

2. Ex-proof electric devices as motors and control units to meet the LNG working conditions;

3. Specially seals ensure a long time of free maintenance to the cold end, up to 3500 hours;

4. Multiple cold end design to fulfill high flow service;

5. Vacuum jacketed cold end minimizes heat loss and lowers liquid’s vaporization;

6. Interlocking system ensure protection from wrong operations;

7. 24-hour persistent performing;

8. All electric components are configured as per anti-explosion requirements;

9. The piston seal is made of special material and the service life of the piston seal is over 4000 hours;

10. Low discharge pressure fluctuation;

11. Fast precooling ;

12. The simple pump head module design facilitates maintenance;

13. The pump has the design of new type gland packing and ultra-long service life;

14. Maintenance is convenient: it merely takes two hours to perform a routine maintenance.

- Previous Product:Liquid CO2 Carbon Dioxide Transfer Pump LCO2 Canned Pump