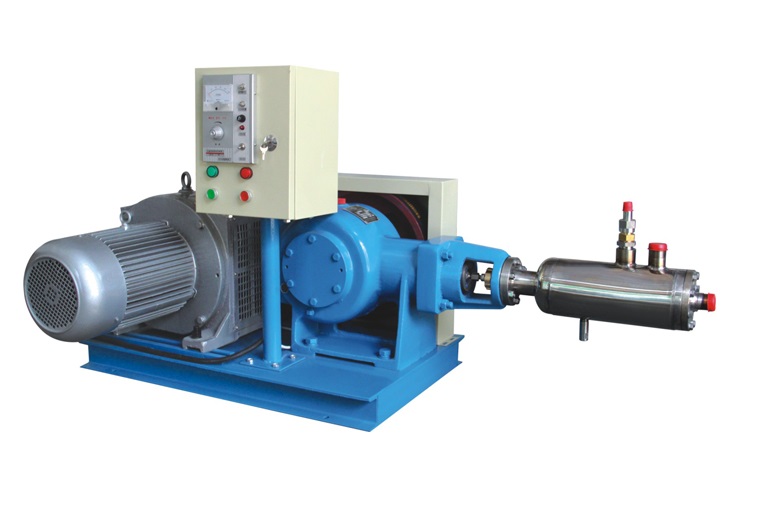

300bar High pressure cryogenic LOX/ LIN / LAr cylinder filling pumps

Cryogenic LOX LIN LAr Reciprocating Pumps for Cylinder Filling

Minwen reciprocating cryogenic liquid oxygen/ nirogen/ argon pumps are applied in the filling system of oxygen, nitrogen and argon. After boosting the pressure of the low- temperature liquid in the cryogenic storage tank, the liquid will go through the high pressure ambient vaporizers, then the high pressure oxygen/ nitrogen/ argon will be filled into the gas cylinders or pipelines.

Minwen cryogenic pumps are stable in performance, easy to operate, convenient to maintain. In proper conditions, its starting time is about 5 to 10 minutes. The pump head can be offloaded separately and reloaded after examination, which would be finished within 2 to 4 hours.

|

Specification of Minwen Cryogenic liquid pumps 200~600liter/hour |

||

|

No. |

Item |

Specification |

|

1 |

Model No. |

BPO-200-600/16.5 |

|

2 |

Type |

Horizontal, single cylinder, piston |

|

3 |

Design temperature |

-196 ºC |

|

4 |

Operating temperature |

-196 ℃ |

|

5 |

Medium |

LOX, LIN, LAr |

|

6 |

Operating pressure |

16.5MPa |

|

7 |

Design pressure |

17MPa |

|

8 |

Inlet pressure |

0.02Mpa~1.6Mpa |

|

9 |

Flow rate |

200-600L/H |

|

10 |

Input power supply |

380V/ 3ph/ 50Hz |

|

11 |

Motor power/ rotation speed |

5.5KW/ 380V/ 50HZ |

|

Supply scope of Minwen Cryogenic liquid pumps |

|||

|

S.N. |

Item |

Specification |

Quantity |

|

1 |

Pump head (cooling end) |

P200-600 |

1 piece |

|

2 |

Transmission case |

D200-600 |

1 piece |

|

3 |

Belt pulley mechanism |

|

1 set |

|

4 |

Skid base |

|

1 set |

|

5 |

Speed-regulation motor |

|

1 piece |

|

6 |

Liquid feeding metal soft hose |

JRD40L-300 |

1 set |

|

7 |

Return gas metal soft hose |

JRD25L-300 |

1 set |

|

8 |

Spare parts and special tools |

|

1 set |

|

9 |

User's manual |

|

1 piece |

|

10 |

Control cabinet |

|

1 piece |