Acetylene Plants C2H2 Generator Filling Stations

Acetylene Plants C2H2 Generator Filling Stations

Propane produces a flame temperature of ~2800℃ when burned in oxygen. Acetylene produces a flame temperature of ~3100℃ along with oxygen. This high flame temperature makes acetylene a suitable choice for gas welding steel.

Acetylene is generally obtained from the reaction of calcium carbide and water: CaC2 + 2H2O → C2H2 + Ca(OH)2 + heat. The manufacture of acetylene is extremely energy intensive. Calcium oxide is mixed with powdered carbon, and the mixture is heated to white hot in a crucible for hours. The carbon slowly reacts with the calcium oxide to form calcium carbide.

Acetylene is the best fuel gas that can be used for welding. It is also useful for brazing, cutting, flame gouging, spot heating, hardening, texturing, cleaning, and thermal spraying of many materials.

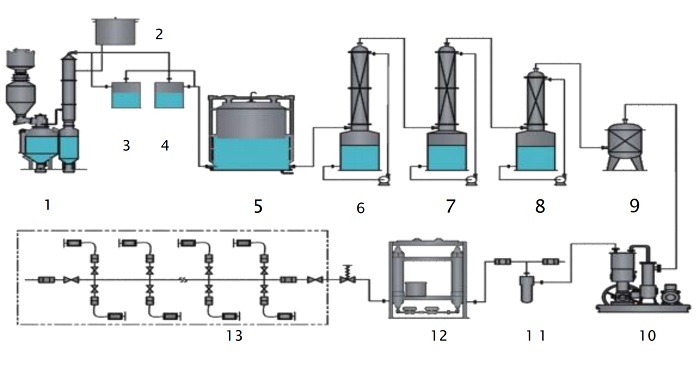

Flow chart of acetylene gas equipment of Minwen acetylene gas plants

1. Acetylene gas (C2H2) generator

2. High level water tank

3. Forward water seal

4. Reverse water seal

5. Acetylene gas holder

6. Primary purification tower

7. Secondary purification tower

8. Neutralization tower

9. Low pressure dryer

10. Compressor

11. Oil water separator

12. Molecular sieve high pressure dryer

13. Filling system

- Previous Product:40L Acetylene Gas Cylinders Standards ISO3807

- Next Product:Calcium Carbide size 50-80mm 5-15mm 25-50mm